with thanks to Chris and Louise Elkington, Grantham, Lincolnshire

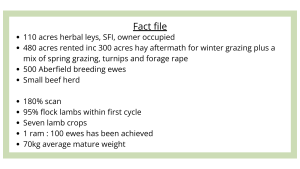

Aware that maternal genetics have a 10-year impact led Chris and Louise Elkington to make Innovis their first choice while establishing a closed flock on their low input forage-based unit.

“We took the opportunity provided by Innovis’s properly performance recorded rams to use EBV information to help us to accurately predict how they would breed on our system, in particular for those invisible maternal traits including milk and ease of lambing,” Chris explains. “Our selection procedure has definitely paid off. We’ve found that the Aberfield SR rams together with a touch of Highlander genetics are leaving ewes that tick all the boxes, and that includes being good on their feet.”

“These Aberfield ewes are averaging 70kg mature weight enabling us to stock more than our previous hungry Mules. They are proving to lamb without assistance, they’re very milky and look after their lambs. They can maintain themselves in BCS 3 all year round off pure forage diets and fertility is reflected in the fact the vast majority – 95% lamb within the first cycle. Furthermore, the flock is achieving a 180% scan which is enough for us on our management system.”

The Elkingtons also use EBVs to select for backfat – we like a lamb with a certain level of fat that will finish off a pure grass and forage diet and deliver a consistent quality carcase rather than a leaner lamb – that’s a trait which is vital to our business.”

Producing a quality lamb carcase 365 is a pre-requisite to the couple’s business branded Gelston Lamb. To ensure an all year-round supply, the flock is split lambed and while the entire crop, apart from replacements, is finished off a sole forage diet to 18kg to 19kg deadweight. A portion is stored overwinter on hay aftermaths and finished on forage rape or turnips.

“Every finished lamb is sold through one of various routes to market including a monthly pop-up farm shop, two farmers’ markets, a catering trailer and online orders. “We’re really busy – we are killing 10 to 20 lambs a week plus two cull ewes,” he says. “However, it’s extremely rewarding to sell direct as it’s great getting back feedback from the people actually eating the end product.”

Turn the clock back 25 years shortly after Chris and Louise met, and they began farming with a couple of ewes on rented land. The flock gradually grew, however establishing a catering business was the catalyst. 2016 and the couple had the opportunity to take on more land farmed by Louise’s parents and began to convert it from arable to grassland, eventually carrying 500 ewes with capacity for further flock expansion.

“Growing our own lamb marketing business has been organic, however it made the big leap in 2023 when we employed a full-time butcher. Having the butchery on site enabled us to develop and perfect our recipes for our award-winning burgers and sausages and establish that vital quality control. It also enabled me to focus more on the farm and drive for further efficiency.”

Chris continues: “Since Innovis offers a choice of breeds to suit the system to maximise gain, when it came to meat ram, then we chose the Aberblack and Abermax with EBVs selected for a positive fat content, ease of lambing and also sound feet, they were the favourites to cross to the early lambing Aberfield flock which we lamb indoors and then turn out immediately afterwards on to an early flush grass.”

Nowadays we would never buy in replacements; managing a self-replacing flock with Innovis genetics which are continuously developing, enables us to maintain its health as well as keep control of the genetics and progress our own breeding programme.

The later outdoor lambing ewes are crossed to the Aberfield SR for replacement purposes. “We cull very hard and our replacements are made by decisions on KPI measurements with financial value – rearing percentage and eight week weight, to enhance unit efficiency and profitability,” he explains. “We are definitely hands off when it comes to lambing, we check the ewes three times a day and we’re able to confidently leave it at that.

“From six weeks post lambing we gradually mob up the ewes up into groups 250 with lambs on to a rotational grazing system comprising clover swards, moving them on every two to three days. We wean at 14 weeks and make the first draw at 16 weeks. Post weaning the lambs rotationally graze with cows and ewes, while those staggered to finish later are introduced to forage crops.”

Chris adds: “Nowadays we would never buy in replacements; managing a self-replacing flock with Innovis genetics which are continuously developing, enables us to maintain its health as well as keep control of the genetics and progress our own breeding programme.”